Cadastral Surveying

Cadastral surveying mainly relies on manual measurement and mapping techniques. It uses surveying instruments to conduct field measurements of geographic space, and then uses mapping tools to draw the measurement results into geographic information in the form of maps or charts.In traditional cadastral surveying, surveyors need to have professional surveying skills and knowledge and be able to use various surveying instruments to conduct field measurements, including distance, angle, elevation and other measurement elements.

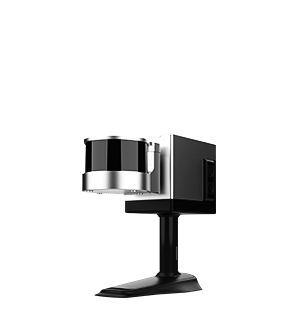

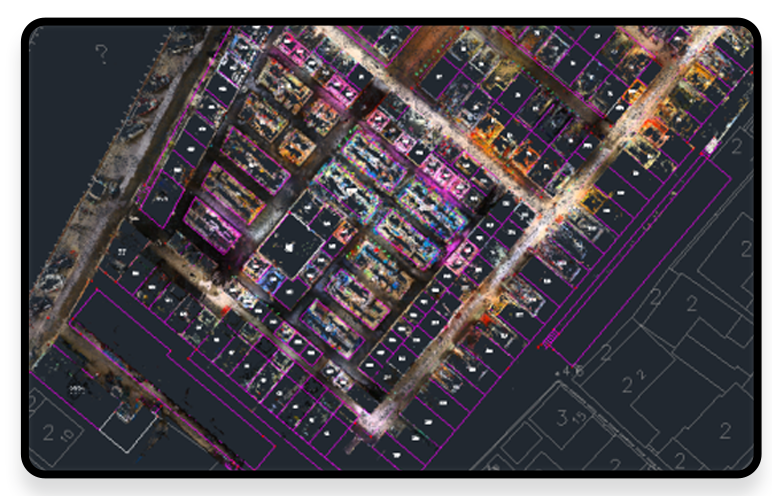

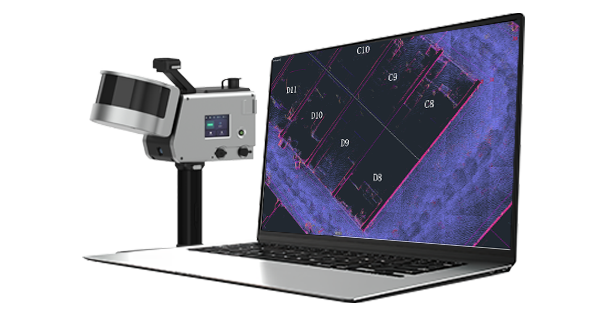

With the continuous advancement of artificial intelligence technology, cadastral surveying is undergoing a digital, automated and intelligent transformation. Through the GoSLAM 3D laser scanning system, we can obtain geospatial data at a faster speed and higher accuracy, which is becoming more and more popular among users.

Industry Pain Points

Advantages

-

Efficient Full-scenes Coverage

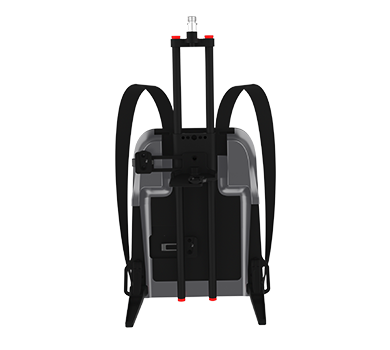

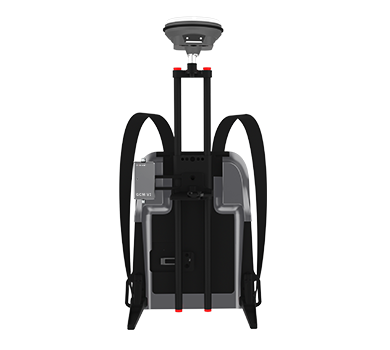

It supports multiple modes such as handheld, backpack, car-mounted, and drone. A single scan can cover an area of several kilometers.

-

Lightweight and Low-cost

The equipment is lightweight and can be operated by one person, saving manpower and transportation costs.

-

Centimeter Accuracy and High Details

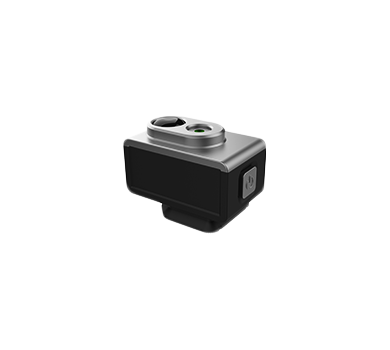

Integrates LiDAR, IMU, and visual sensor to achieve high-precision scanning and 360° panoramic capture in complex scenes, avoiding missed details during measurement.

-

Intelligent Application Expansion

Digital Twin Compatibility: Real-life 3D visualization, seamless data connection with BIM/CIM platform, and support for full life cycle management of facilities.

Solutions and Related Products

The GoSLAM mobile measurement system can obtain 3D spatial information of complex on-site environments and spatial targets, quickly reconstruct the 3D model data of the target, and objectively reflect the true morphological characteristics of the object. The non-contact data acquisition method can collect data without touching the surface of the object. Professional analysis and processing software provides convenient operation for the true restoration of the building form.

Its specific advantages including:

■The device is small in size, light in weight and can be remotely controlled.

■Non-contact scanning method reduces the risk to workers.

■Use professionally certified analysis software to obtain authentic and reliable results.

■Since near-infrared invisible laser beams are being used, data collection can be performed regardless of whether the environment is bright or dark.

■The application of result data is rich and flexible, which facilitates digital archiving and comparative analysis.

Workflow

Data Collection

Assemble and power on the device, then use a mobile phone to remotely control the device for mobile data collection.

Data Processing

The device can be controlled to perform internal processing and automatically process data by the APP.

Result Export

Data can be exported via USB, network cable or WiFi.