Silo Measurement

Silo measurement is a key link in grain storage, building materials production and logistics supply chain management. Traditional measurement methods (such as manual sampling and weighing, mechanical level meters) face significant technical challenges in silo applications.

With the development of 3D laser scanning technology, mobile SLAM (Simultaneous Localization and Mapping) technology has become an innovative solution for silo measurement due to its fast, high-precision and non-contact characteristics.

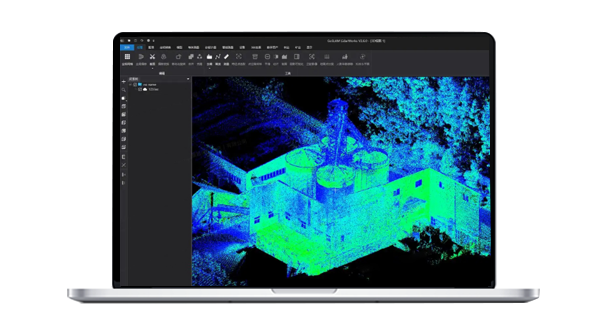

This technology can quickly obtain 3D point cloud data of piles through the integration of laser radar and SLAM algorithm, and realize volume calculation, dynamic monitoring and digital management with professional software, significantly improving the level of intelligence in the industry.

Industry Pain Points

Advantages

-

Efficient and Accurate

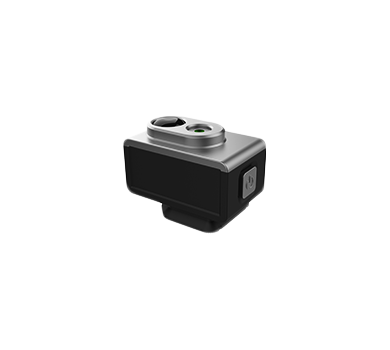

The single-point acquisition efficiency is increased by 5-10 times, the scanning speed reaches 320,000-640,000 points/second, and large-scale silo pile data acquisition can be completed within 10 minutes.

-

Full Scenes Coverage

Supports wide operating temperature range of -35°C to 55°C. With high protection level, it can adapt to scanning operations in complex working environments.

-

Comprehensive Data

Acquire high-precision 3D point clouds, panoramic images and absolute coordinates, and support volume calculation, contour line generation, and dynamic comparative analysis.

-

Intelligent Management

The supporting software automatically generates reports, supports connection with third-party systems, and facilitates digital warehouse management.

Solutions and Related Products

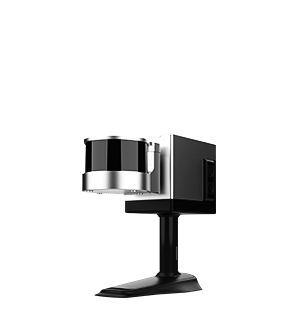

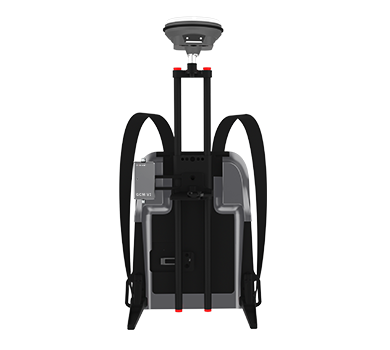

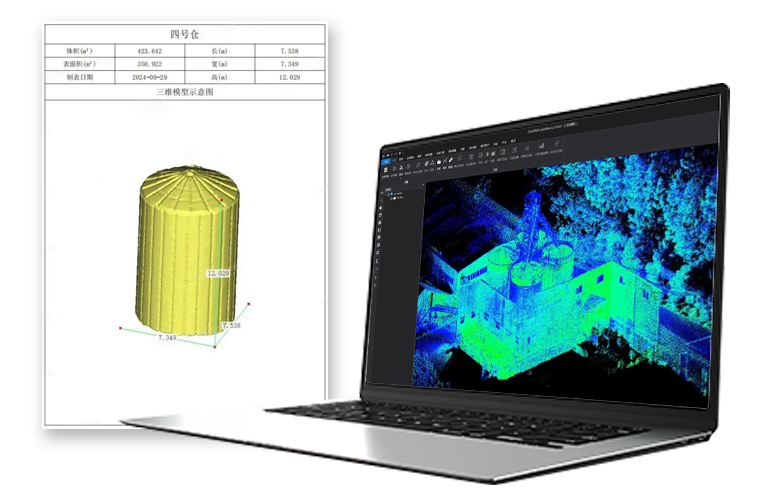

The GoSLAM mobile measurement system 3D scanner has significant advantages in pile measurement. It can improve work efficiency, measurement accuracy and data comprehensiveness of pile measurement, especially in large piles and intelligent digital material piles.

Main Advantages:

■ Real-Time Process: Once the scanning is completed, a usable point cloud can be generated without secondary processing.

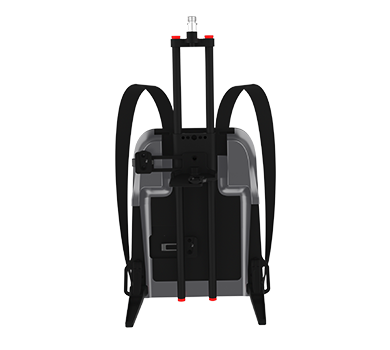

■ Multi-platforms Adaptation: Supports multiple mounting methods such as handheld, backpack, extension pole, drone, track deployment, fixed deployment, etc., to flexibly handle different scenarios.

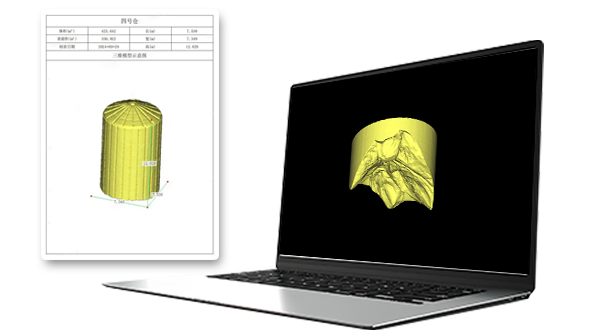

■ Intelligent Software Support: LidarWorks software provides functions such as point cloud denoising, pile extraction, and volume calculation, and can generate professional reports with one click.

■ High-precision Guarantee: Point accuracy is up to 1cm, combined with anchor point processing technology to ensure measurement stability in large-scale low-feature scenes.

Workflow

Data Collection

Assemble and power on the device, then use a mobile phone to remotely control the device for mobile data collection.

Data Processing

The device can be controlled to perform internal processing and automatically process data by the APP.

Result Export

Data can be exported via USB, network cable or WiFi.