Mine Tunnel Measurement

As the scale of global mining resource development expands and mining depth increases, the traditional 2D plane measurement model can no longer meet the refined needs of modern mine management. Currently, most mining areas still rely on single-point measurement equipments such as total station and theodolite, which are unable to fully reflect 3D spatial information such as ore body morphology, tunnel structure, slope displacement.They also lack high-frequency monitoring capabilities for key parameters such as ore layer thickness and dynamic changes in reserves.

Industry Pain Points

Advantages

-

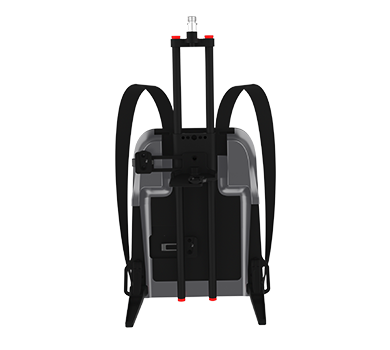

Zero-Touch Operation

There is no need for personnel to enter goafs or dangerous tunnels, and data collection in high-risk areas can be completed through scanning with an extension pole.

-

High Precision Survey

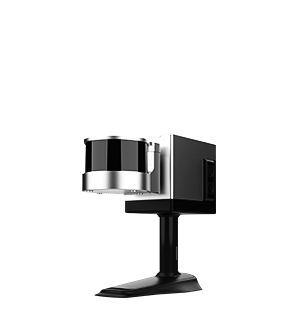

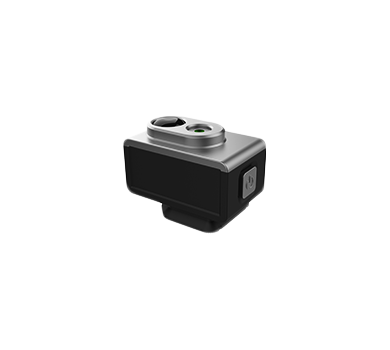

The technology is combined with multi-lines laser radar to achieve high-precision point cloud modeling of tunnel sections and ore body contours.

-

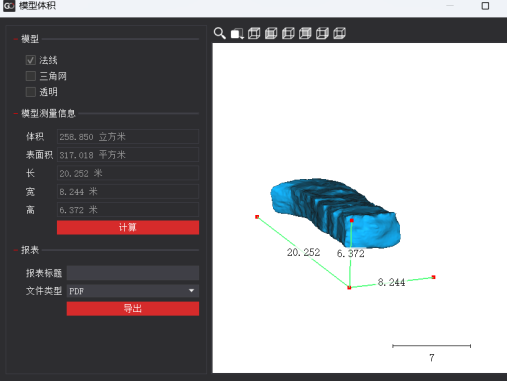

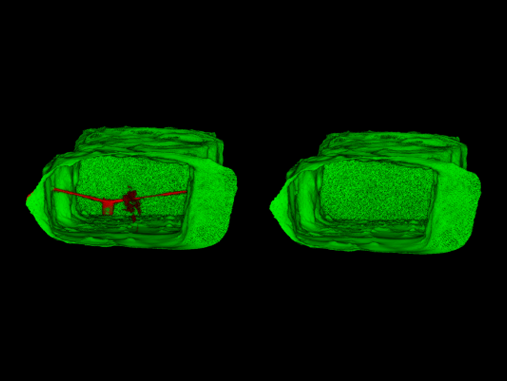

Accurate Volume Calculation

The empty area point cloud can automatically generate a triangulated network model, calculate the volume, and optimize the support and filling scheme.

-

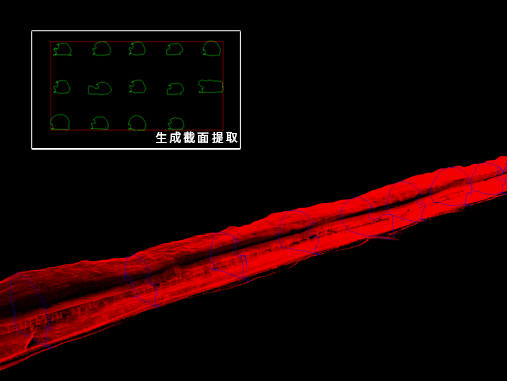

Automatic Vectorization

The software can be used to slice the lane and generate the lane's DXF file in one click.

-

Freely Cutting Vertical and Horizontal Sections

For inclined ore bodies and staggered tunnels, profiles in any direction can be quickly generated to be an assistant in mining design.

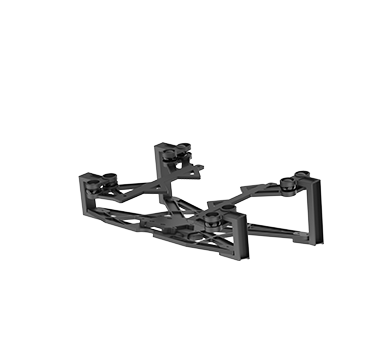

Solutions and Related Products

■ Compared with traditional manual line drawing method, the automatic generation method based on the GoSLAM scanner can greatly improve efficiency and accuracy.

■ 3D scanning can be used to compare with the construction and design models in real time, it can quickly correct deviations and ensure construction schedule.

■ Scan hidden projects and complex areas at coal mine construction sites to identify potential safety hazards, such as geologically unstable areas, tunnel deformation, etc.

■ Accurately perform 3D scanning and data recording. Convenient to establish digital archives of equipment and facilities, realize full life cycle management of equipment, and improve the efficiency of equipment maintenance and management.

Workflow

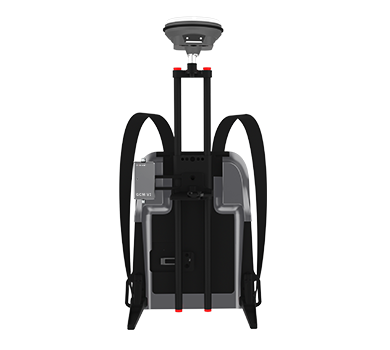

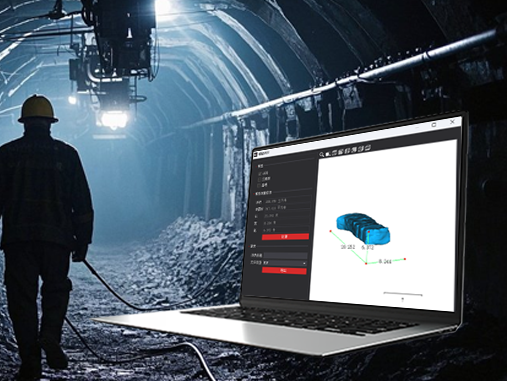

Data Collection

Assemble and power on the device, then use a mobile phone to remotely control the device for mobile data collection.

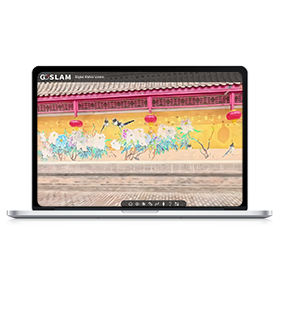

Data Processing

The device can be controlled to perform internal processing and automatically process data by the APP.

Result Export

Data can be exported via USB, network cable or WiFi.