Coal Mine Measurement

In order to achieve the development goal of smart coal mines and ensure the personal safety of coal miners, measurement tools and 3D display tools are particularly important. With the continuous advancement of science and technology, digital surveying and mapping technology has been widely used in coal mine geological surveying, which has improved the efficiency of geological exploration and mining, while also reducing exploration costs and risks.

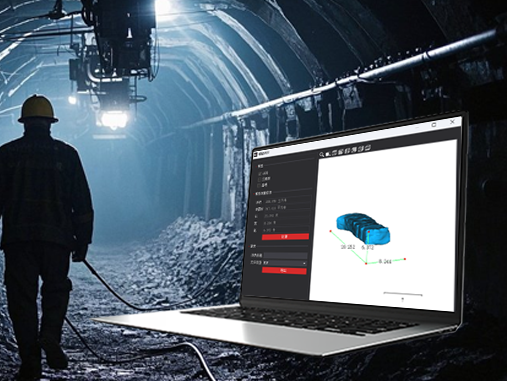

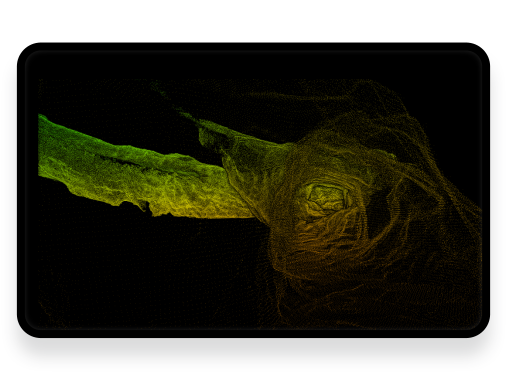

GoSLAM presents the measured data in the form of an intuitive 3D model, allowing coal mine managers and technicians to have a clearer understanding of the actual situation of the coal mine.

Industry Pain Points

Advantages

-

Improve Efficiency and Increase Production Capacity

Fast and effective mapping methods have brought significant improvements to all production links of coal mines. In the coal mine planning stage, accurate and fast GoSLAM mapping data can help engineers plan the mine layout more scientifically, reasonably arrange the direction of the tunnel and the mining area, and avoid waste of resources and increased mining difficulty caused by unreasonable planning.

-

Rapidly Generate 3D Models

The GoSLAM system can quickly generate a 3D model of a coal mine based on its fast data collection capabilities. It is also used for internal 3D modeling and drawing. In the coal mine scene, it can help workers quickly and intuitively understand the topography and distribution of the coal mine, grasp the production progress, and provide strong support for the planning and management of smart coal mines.

-

Assist Production Management

Through the rapid generation of 3D models, coal mine managers can monitor the production status of the coal mine in real time, promptly identify problems in the production process, and take corresponding measures to make adjustments.

-

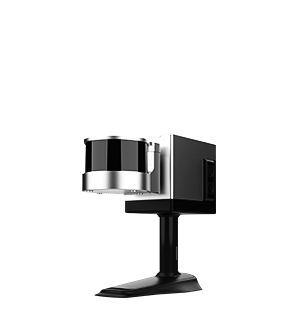

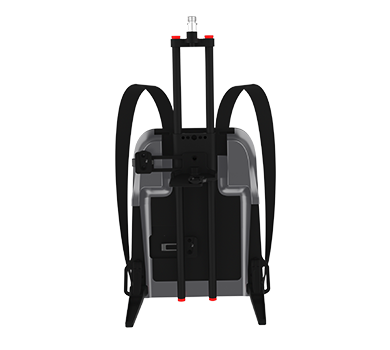

Intrinsically Safe Explosion-proof Certification Ensures Safety

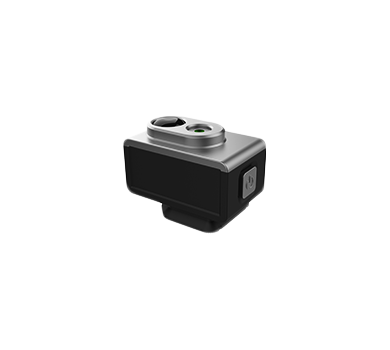

GHJS12 explosion-proof mobile 3D scanner has intrinsic safety explosion-proof certification and complies with the standards for electrical equipment in explosive environments. In dangerous environments such as coal mines where flammable and explosive gases exist, this certification ensures that the sparks and thermal effects generated by the equipment under normal operation and specified fault conditions cannot ignite the explosive mixture in the surrounding environment, effectively reducing the risk of accidents such as explosions caused by equipment and ensuring the safety of coal mine measurement operations.

-

Accurate Measurement Reduces Hidden Dangers

The high-precision measurement function of the system can help workers more accurately understand the geological structure and roadway stability of coal mines, and discover potential safety hazards in advance, such as geological faults and roadway deformation. By taking reinforcement and support measures in a timely manner, accidents such as gas explosions, water seepage, and roof falls can be effectively avoided, thereby reducing the accident rate of coal mines and ensuring the safety of coal miners.

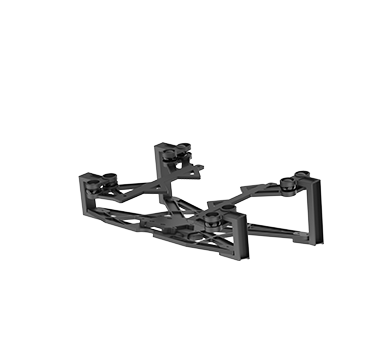

Solutions and Related Products

■ Generate panoramic 3D maps of terrain and obstacles with one click, optimize construction layout and transportation routes, and reduce site conflicts by more than 30%.

■ 3D scanning data can be used to compare the construction and design models in real time, quickly corrects deviations and ensures construction schedule.

■ Scan hidden projects and complex areas at coal mine construction sites to identify potential safety hazards, such as geologically unstable areas and tunnel deformations.

■ Accurately perform 3D scanning and data recording. Convenient to establish digital archives of equipment and facilities, realize full life cycle management of equipment, and improve the efficiency of equipment maintenance and management.

Workflow

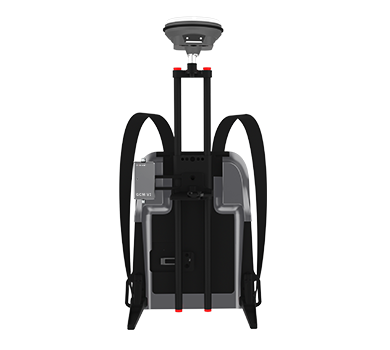

Data Collection

Assemble and power on the device, then use a mobile phone to remotely control the device for mobile data collection.

Data Processing

The device can be controlled to perform internal processing and automatically process data by the APP.

Result Data

Data can be exported via USB, network cable or WiFi.