Open-Pit Mine Surveying

In the field of open-pit mining, fast and accurate measurement and monitoring are crucial to ensuring production safety, improving resource utilization and achieving sustainable development. With the development of technology, traditional measurement methods are gradually unable to meet the complex and changing needs of modern open-pit mines.

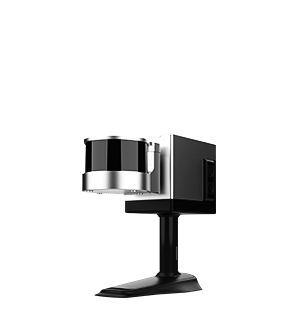

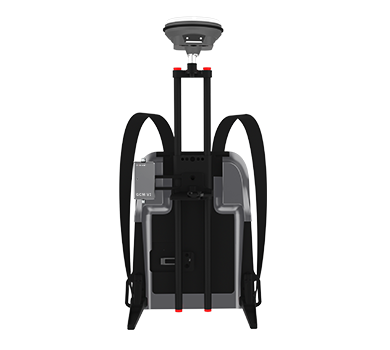

The application of GoSLAM equipment combined with drones in open-pit mines provides an innovative path to solve industry pain points and improve mine management level.

Industry Pain Points

Advantages

-

Efficient Data Collection

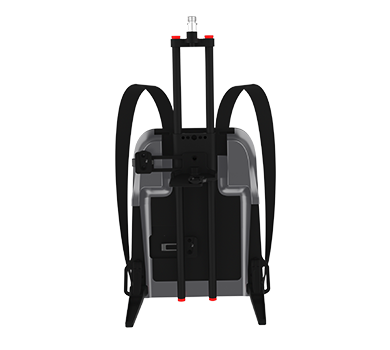

Drones equipped with GoSLAM devices can quickly cover large open-pit mine areas. In open-pit mine surveys, ore pile surveys, and conventional topographic surveys, massive amounts of data can be acquired at high speed and efficiency.

-

Obtain High-Precision Data

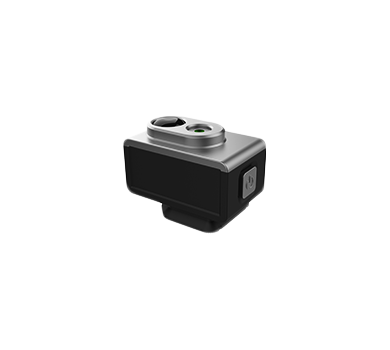

GoSLAM equipment has high-precision measurement capabilities, combined with the flexible flight of drones, it can obtain accurate data on quasi-topography, ore bodies and ore piles. Its high-precision scanning data provides reliable data support for mine mining design, resource reserve assessment, etc.

-

Reduce The Risk of Personnel Exposure

By using drones for measurement and inspection, surveyors do not need to enter dangerous areas, effectively reducing the risk of exposure to dangerous environments such as open-pit mines and tailings ponds, and ensuring the safety of personnel's life and health.

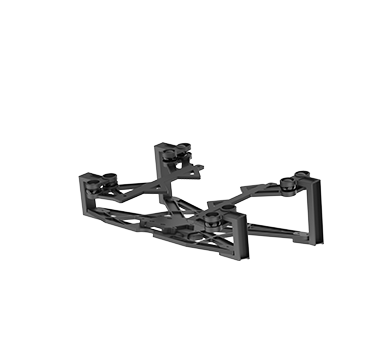

Solutions and Related Products

■ Mining Progress Monitoring: UAVs can regularly scan open pits to obtain a 3D model of the pit. By comparing it with the mining design model, the mining progress can be monitored in real time, and over-excavation and under-excavation in the mining process can be discovered in a timely manner, providing a basis for adjusting the mining operation and ensuring that the mining work proceeds in an orderly manner as planned.

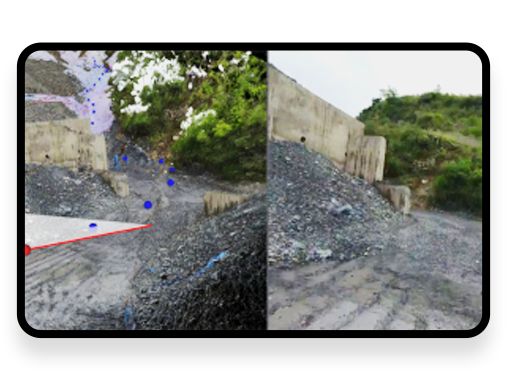

■ Slope Stability Monitoring: Use GoSLAM equipment to perform high-precision measurements on the open pit slopes to obtain the topographic data and deformation information of the slopes. By analyzing the displacement trend of the slopes, predicting the potential sliding risks of the slopes, and taking reinforcement and support measures in a timely manner, the stability of the slopes and the safety of mining operations can be guaranteed.

Workflow

Data Collection

Assemble and power on the device, then use a mobile phone to remotely control the device for mobile data collection.

Data Processing

The device can be controlled to perform internal processing and automatically process data by the APP.

Result Export

Data can be exported via USB, network cable or WiFi.